The Problem-Solving Powers of Variable Speed Drives

Lei Gommers, Global Business Development Manager, Agriculture, ABB Drives explores the pivotal role that variable speed drives (VSDs) working with electric motors can play in addressing the agricultural sector's toughest challenges.

How Motors Are Used Within Agriculture

The agricultural industry has always been at the forefront of technological advancements in order to meet the increasing demands of food and fuel production. Motors have revolutionised the way farming operations are conducted, providing improved efficiency, and productivity.

Farmers Dig Ohio Company's Efficient Coulter

The device reduces fertilizer loss, helps farmers cover more acreage in less time and offers greater durability due to components that resist corrosion in the harsh agricultural environment.

Being a Good Steward

Wastewater treatment is serious business. Gearboxes from NORD DRIVESYSTEMS help this small community process up to 15 million gallons of it daily, without fail, with no surprises.

Reaping Good Harvest: Artec Leo Offers Innovation to Improve Harvesting in France

The company 3D scans parts with high precision to adapt or reproduce them for machine modifications like a core cleaning module or an enhanced sowing system.

Records 1 to 5 of 5

Featured Product

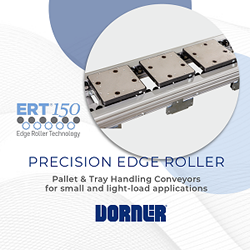

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.